What is Digital Print Fabric and How is it Made?

We have been great guardians of the rich handloom legacy of India at Huts and Looms. We believe in the exquisite craftsmanship of weaving, the natural beauty of fibres, and the legends and histories, thrilling and sincere, woven into every fibre of our cotton, silk and tissue saree. But the world of textiles is never the same, and the next, ground-breaking art has come, which enables one to amazingly colour, detail, and customise digital print fabric.

Although we glorify the tedious art of the handloom, we are also thrilled by the fact that in addition to the limits of design, the methods of modern textile printing may be used to enhance design. Think of the sensitive and complicated artistry of the vision of a great weaver and transferring it onto cloth in such a way that it is photorealistic; that is the strength of the innovation. Together with us, we will investigate what this game-changing method is, the process of it, and how it proves to be transforming the potential of fabric design.

What is Digital Print?

When we mean digital printing in the textile industry, we are talking 118 about a high-tech process where colourants are applied on the fabric surface using high-speed, large-format inkjet printers. You will understand the basic idea, should you ever have run a printer at home, but the size and fineness of digital fabric printing is astonishing.

Before the introduction of this technology, the industry used primarily processes such as block printing and screen (or rotary) printing. These conventional methods are gorgeous, however, having intrinsic drawbacks: every colour must be printed using a separate screen and therefore designs in a broad range of colours or delicate gradations are prohibitive in complexity and too expensive.

What is digital print fabric presently makes designers bypass these drawbacks completely. The printer can print out thousands of the tiniest drops of ink and reproduce an endless palette of colours as well as the most fascinating yet complicated designs imaginable, beautiful photographs to the tiny artistic details that would be created by a single digital file. This move has increased creative freedom as well as brought about a more sustainable on-demand production era.

Digital Print Fabric Production: Production Process

The process of making a digital print fabric that is rich and quality and full of bright colours is an accurate process that combines digital technology with chemicals and special textile printing techniques. This process involves several steps that make sure that the end product is not only a beautiful one, but also durable, as well as colourfast.

Step 1: Production of digital designs

The design file is used to start the whole procedure. The textile artist completes his work by using an advanced computer-aided design (CAD) software to complete the pattern. This colour and coordinate information is all stored in the high-resolution file, and the printer will read it. Due to the capabilities of digital printing, the designer can use as much or as little colour as they desire, something that would not have been the case with the other traditional techniques.

Step 2: Pre-treatment of the Fabric (Pre-treatment)

This is one of the steps that should not be compromised to attain brilliance and longevity. Its raw and white base fabric is chemically treated in a process sometimes referred to as a padding process. This pre-treatment solution is used to prime the textile, making it open up so as to absorb the maximum amount of ink and chemically bond it with the dyes. Unless the pre-treatment was done to the right, the resulting print would be dull and blurred, and it would easily fade away.

Step 3: The Printing Phase

The already pre-treated fabric is then passed through the wide-format digital textile printer. This is the very place where the digital print cloth process is implemented. Printheads of the specific industrial factory are commonly filled with hundreds of tiny nozzles that accurately spray microscopic amounts of ink (usually water-based and green) onto the moving cloth. The digital file is read, the colours are applied in a series of layers with perfect registration so that the design is reproduced exactly as intended, despite its level of sophistication.

Step 4: Fixing and Curing

As soon as the ink has been applied to the fabric, there must be a permanent setting of the ink. It is done by high-heat, normally using steaming or dry heat. Heat triggers a chemical reaction which permanently fuses the molecules of the dye to the fabric fibres. This case of the curing is the key to guaranteeing high-quality wash fastness and rub fastness, that is, the colours will not fade even after years of wear and washing processes.

Step 5: Washing and Finishing

Lastly, a thorough post-wash of the cured fabric is made. This rinsing process eliminates any unused ink, unused pre-treatment chemical, as well as any unbound dye molecules. The garment is dried and due final finishing of the garment is provided to provide the ideal drape, tender touch and crisp feel that makes a Huts and Looms fabric so comfortable to wear. The end product is a high-quality digital print fabric that is set to be made into splendid clothes.

Digital Print Fabric Types

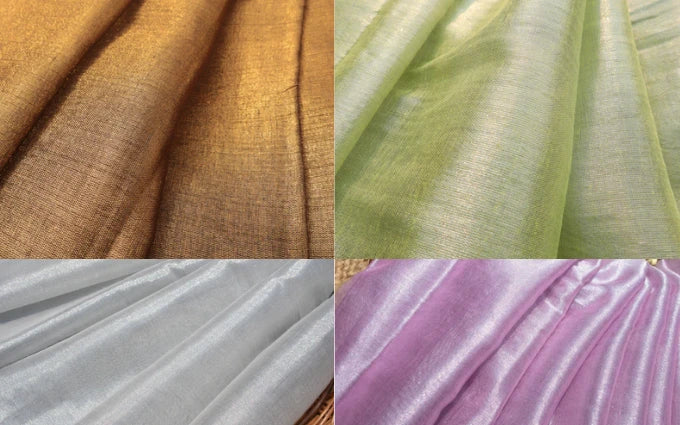

The ability to print on a wide variety of materials is also among the greatest advantages of printed fabrics using digital printing, as long as the appropriate ink set is applied. This flexibility enables Huts and Looms to provide high-definition designs on different textiles to our customers:

Natural Fibres (Cotton, Silk, Linen): These are frequently printed with reactive dyes, which bind perfectly with protein fibres as well as cellulosic fibres. This would be the combination of the two bests, the ease of breath of cotton or the decadence of silk, but with some very elaborate and colourful prints. This process is often used in our Mul Cotton and handwoven silk blends to provide an exceptional finish of the garment.

Synthetic Fibres (Polyester): This type of fabric is normally printed through the sublimation process, whereby the design is printed first on the transfer paper and then pressed onto the polyester. Then, in heat, the ink solidifies into a gas that is embedded in the synthetic fibres. This is very strong and gives very bright colours, ideal in the contemporary bend of lightweight coverings.

Viscose and Modal: Soft and capable of taking dye in large quantities, these are also the fabrics that present a good alternative to digital printing to digital printing; they provide a luxurious tactile feeling and outstanding colour brightness.

Caring Tips for Digital Print Fabrics

The present fixing process makes the digital prints more resistant as compared to some of the traditional prints. But to keep your digital-printed cloth of Huts and Looms alive and lively, there are a few simple rules of care, which we would give you:

Looking after Digital Print Fabrics: The fixing process is contemporary, which makes digital prints stronger compared to certain traditional prints. But to maintain the life and vitality of your printed cloth of your digital print Huts and Looms, we suggest a few simple caring suggestions:

See the Care Sign: It is always best to follow the special instructions on the garment, as this is the only way they can be best treated: silk should not be treated like cotton.

Turn Your Garments Inside Out: Refer to step one, but inside out. This will reduce the abrasion of this print surface, which protects the design clarity.

Select Cold Water: Wash with cold water after application of mild, pH-neutral detergent. This is less harsh to dyes and aids in retaining colour brightness in the long run.

Air Dry or Low Heat: High heat drying should be avoided as this may cause damage to the fibres and may imply fading of the dyes. Wash on a full load machine or better still, dry it either by tumbling or leaving in the shade to dry.

Iron with Caution: When the ironing is required, be sure to iron the garment inside out on low to medium heat, or use a press cloth. Do not subject the printed surface to intense, direct heat.

Conclusion

Digital print fabric technology is not a substitute tool over the original weaving, but it is an advanced instrument that broadens the artistic realm of textile designing. In the case of Huts and Looms, it is the fact that honouring the past and having the future at the same time. It is a sophisticated way to introduce you to designs of unmatched detail, depth of colour and personalisation and do so without sacrificing our waste reduction drive according to our environmental footprint, as compared to the older forms of printing.

When you know the meaning of digital print fabric and the painstaking process of its manufacture, you will be able to appreciate the distinctive process of these contemporary masterpieces. It is a real synergistic creation of art, the steadiness of the handloom mingled with the unlimited imagination of the digital brush. Understand the beautiful options of digital printing and leave the colourful patterns to open a new, colourful dimension of your personal style.