The Making of Dhaniakhali Sarees: History, Fabric, and Craftsmanship

Our philosophy at Huts and Looms is based on the magic of the handloom, where a single knot, thread, and motive bear the murmur of tradition. Today, we are taking you on a trip to a little community in the Hooghly district of West Bengal, where the name of the place is identified with a pleasant, warm, and most adorable garment, the Dhaniakhali saree.

Not merely an item of clothing, the Dhaniakhali handloom sarees are a daily symbol in Bengal. These are symbols of reassurance, stability, and a centuries-old legacy. They become the ideal representation of a classic that will cross with the market to a morning date without any trouble. That is why you are ready to discover the secrets of these fantastic weaves. We will now get down to the history of Dhaniakhali sarees and the special Dhaniakhali weaving process, which gives life to them.

History Dhaniakhali Sarees History of Dhaniakhali Sarees

The Dhaniakhali sarees are a tale of perseverance and survival as their own story in the long history of Bengal textile. This weaving tradition is based in the town of Dhaniakhali and has thrived for more than a century.

This region was renowned when it was in its early years as being fine and crisp dhotis. When the demands shifted at the beginning of the 20th century, the master weavers accommodatingly switched to sarees, preserving the tight weave and heavy fabric that characterized their occupation.

The traditional Dhaniakhali, in days gone by, was quite minimal, and with an understatement, a plain, natural grey or kora body in contrast with a heavy, deep border of black or deep red. It was marked by this pointless simplicity, which became its signature sophistication. The first official introduction of dyed yarn did not happen until the 1940s, which introduced the rich colours and expanded possibilities of design we now have.

Following the partition of Bengal, the Dhaniakhali handloom sarees continued to grow in political and cultural grounding, and this made the saree one of the most relevant traditional handlooms in India, among Shantipur and Phulia. There is even a Geographical Indication (GI) status of the saree today, and this is the testimony of its unique localized craftsmanship, which we at Huts and Looms are determined to retain.

Clothes worn in Dhaniakhali Sarees

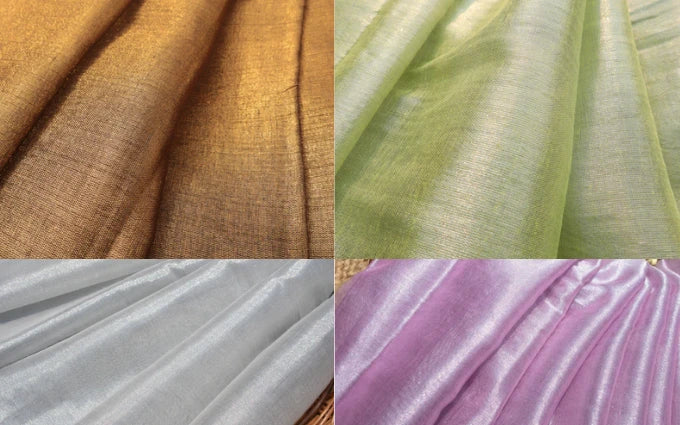

The texture and drape of a Dhaniakhali is what makes it have a unique identity. It is reputed to be a little heavier and crisper than an average soft Bengali cotton saree, creating the effect of its inordinate stability and carrying its folds beautifully.

High-quality cotton is the fibre of Dhaniakhali saree fabrics, and it has remained so. Weavers classically employ a narrow number of count of cotton yarn counts, usually between 80s -100s in the warp (lengthwise threads) and the weft (crosswise threads).

It is that cautious application of this particular count, along with a greater number of weft threads (picks per inch) than warp threads (ends per inch) that forms that distinct tight weave. It is the compactness that gives the saree its marvelous crispness and durability. Although nowadays it is possible to add a hint of silk or art silk (viscose rayon) to create a glossier touch, the heart of a real Dhaniakhali is its breathable, handloom cotton.

Shop The Look!

The Crafts and Process of Weaving

The preparation of Dhaniakhali sarees is a ceremony of waiting, ability, and crude strength. All this is done on the old-fashioned throw-shuttle handloom, and an average saree can take a skilled weaver between two to five days to weave, depending on how intricate the design is.

The Dhaniakhali Method of Weaving

Yarn Preparation: The yarn made out of high-quality cotton is obtained and then carefully dyed and dried. This is a deep and even-coloured process which is labour-intensive.

Loom Instructions: The warp threads that have been dyed are hung on the handloom. This is an important process where tension, thread count is carefully measured. Mostly, weavers work with the help of a time-honored reed, a bamboo plant, called Sar, produced locally and adding to the texture of the fabric and ethnic appearance.

Weaving the Body: The weaver uses his hand to operate the shuttle by interweaving the warp and the weft. It is the dense weave most commonly used with a dobby or jacquard connection to greater border designs, which makes the Dhaniakhali weave.

The Signature Motif: The masterpiece feature of this saree is the pallu (anchal), and it can usually have the unique Khejur Chori (date branch) or Dhaner Sheesh (paddy stalk) motif. This design pattern is made by a combination of special woven threads of cotton which are twisted, using two contrasting colours, and at a glance, the original Dhaniakhali weave is recognised.

It is a complicated Dhaniakhali weaving technique representing the masterful work of the generations of the Tantubay and Basak weaving families. One of these sarees covers you with the heritage of the hardworking devotion of a family.

The way to determine authentic Dhaniakhali Sarees

When you go out and get something with heritage, you should be able to know that it is the real deal. These are some of the methods of identifying a real Dhaniakhali saree:

The Textile: It must be a bit coarser and crosser than other Bengali cottons, such as at Shantipur or at Phulia. The garment is well-tailored and is not very loose.

The Weave: The weave should be thick and even. The tight construction is visible should you put it in front of a light. You may also observe that the weft threads are somewhat more than the warp ones.

The Border: The Border, which is traditionally a deeper, contrasting border colour, such as red, black, and Blue, can be striking (typically 1.5-2 inches) and usually has a slightly irregular curve.

The Pallu Motif: The pallu is the search engine for the trademark of Khejur Chori or a paddy stalk design woven on the pallu. The pattern that builds on this unique, recurrent V-like pattern is the Dhaniakhali signature.

Dhaniakhali Sarees Care Tips

When properly maintained, the Dhaniakhali saree is a life companion. It is made of durable cotton, and thus relatively easy to maintain:

First Wash: It is preferable to do the first wash in a dry cleaning, which is meant to fix the dyes.

Frequent Washing: To wash using cold water and a non-alkaline detergent of low concentration. Do not soak extensively.

Starching: To achieve the characteristic crispness, keep it light after every wash to restore it put back to its traditional shape.

Drying: Dry in the shade. When subjected to direct sunlight, cotton colours fade with time.